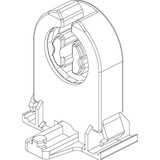

Vimar G13 Fluorescent Lamp Holder, 2A 250V, Rotor-Type, Screw Fixing, Brass Contacts, 80C Rated, White Housing

-

Perfect Fit, Guaranteed

Get the right part every time

-

Expert Support

Our in-house specialists know our products inside and out

-

Enhanced Value & Service

We go beyond the sale with professional and balanced services

-

Wordwide Delivery

Enjoy hassle-free worldwide delivery

Overview

The Vimar VM02463 is a rigid, screw-fixed lampholder for G13 fluorescent tubular lamps, rated 2A at 250V. It uses a rotor-type contact arrangement with brass contacts, and it is rated for continuous operation up to 80 C.

This part is typically used as a replacement when a fluorescent tube socket has loosened up, shows heat wear, or starts causing intermittent lamp contact from vibration. It mounts with screws and connects via terminals, making it a straightforward swap in many existing fluorescent fixtures found on boats.

Key features

- G13 lampholder for fluorescent tubular lamps

- Electrical rating: 2A, 250V

- Rotor-type contact style for secure lamp engagement

- Brass contacts for stable electrical contact

- Screw fixing with terminals for a solid, serviceable installation

- Rated operating temperature: up to 80 C

- White finish that suits many fixture interiors

Compatibility and fit

This lampholder is meant for lamps with a G13 base, which is common on many linear fluorescent tubes. Before ordering, confirm the lamp type used in your fixture and that the fixture body has the right mounting position for a screw-fixed, rigid lampholder with terminal connections.

On board, it is most often used in older cabin, utility, and machinery-space fluorescent fixtures that are fed from shore power circuits or an inverter. Match the circuit voltage and your existing ballast or control gear to the fixture requirements.

Installation and setup

Isolate power at the breaker before servicing any lighting circuit. Mount the lampholder securely, terminate the conductors at the terminals, and keep wiring supported so the connection does not carry cable strain in areas that see vibration.

Because fluorescent fixtures on boats can live in humid spaces, make sure the fixture is properly closed up after installation and that connections stay protected from condensation and spray.

Maintenance and care

During routine lighting checks, look for loosened mounting screws, signs of heat discoloration, or lamp ends that show poor contact. Keeping the tube ends clean and the fixture dry helps maintain consistent starting and reduces flicker caused by contact issues.

We ship all in-store (FL) stock orders the same day if placed before 3 PM EST, Monday through Friday. Orders placed after this time will ship the next business day. Orders fulfilled from other warehouses or manufacturers may not ship the same day. If an item is out of stock, we will notify you promptly.