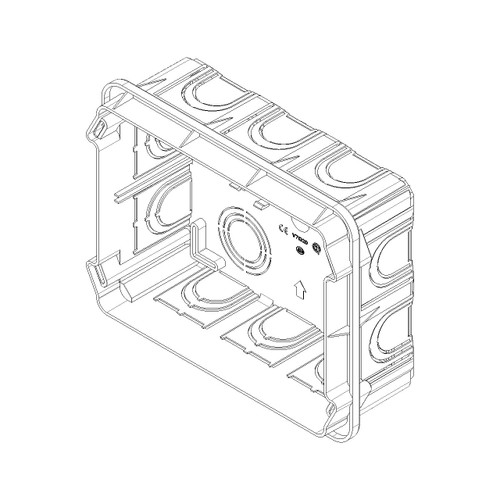

Vimar 12/14-Module Flush Mounting Box, For Masonry Walls, Rectangular, 134x180x50 mm, Halogen-Free Plastic, Glow Wire 650C, 20/25 mm Conduit Knockouts, Light Blue

-

Perfect Fit, Guaranteed

Get the right part every time

-

Expert Support

Our in-house specialists know our products inside and out

-

Enhanced Value & Service

We go beyond the sale with professional and balanced services

-

Wordwide Delivery

Enjoy hassle-free worldwide delivery

Overview

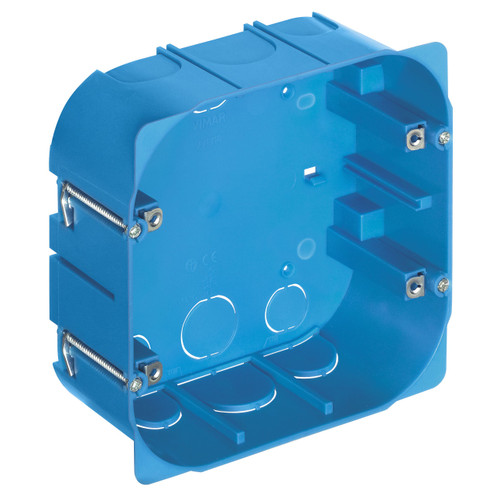

The Vimar VMV71320 is a 12/14-module flush mounting box for masonry walls, sized for larger multi-module switch and outlet layouts. The box footprint is 134 mm x 180 mm with a 50 mm inner depth, giving you room to dress conductors cleanly behind the devices instead of forcing tight bends.

It is built with 14 inlets and knockouts that suit 20 mm and 25 mm conduit runs, which helps when you are feeding multiple circuits into one location. Because it is rated IP00, it belongs in dry, enclosed interior spaces where the front devices and cover plate provide the finished protection.

Key features

- 12/14-module flush box format for multi-gang device groupings in one wall location

- Made for masonry walls with flush-mounted installation

- 134 mm x 180 mm overall size with 50 mm inner depth to keep wiring manageable behind the devices

- 14 inlets with knockouts for 20 mm and 25 mm conduit paths

- Halogen-free plastic body with glow-wire resistance to 650 C

- Patented rack for fixing a dividing screen when separation inside the box is needed

- Zinc-plated fixing lugs help threads stay cleaner during installation and rework

- IP00 protection level, intended to be used inside a finished wall system rather than exposed areas

Compatibility and fit

This box is intended for installations that use the 12/14-module format and require a rectangular flush box behind the finished devices. Confirm you have a masonry wall build-up that can accept the box depth, and plan conduit entries so the 20 mm or 25 mm runs land on the knockouts you want to use.

Installation notes

On a typical masonry install, the box is set in place and plastered flush so the device mounting points remain square and accessible. With a larger box like this, it helps to map conduit routes early so the inlets you use do not crowd the device area once conductors are pulled.

If you need separation between groups of conductors inside the same cavity, the internal rack supports fitting a dividing screen so the layout stays organized.

Use on board

For marine projects, this style of flush box is most common in shore-side or onboard interior refits where the wall construction is masonry or a similar solid build-up, such as crew areas or service spaces in facilities around the marina. It is not a good match for locations exposed to spray, washdowns, or persistent damp, and it is generally not the right choice for thin fiberglass panels or hollow partitions.

Maintenance and care

Once installed, keep the surrounding wall area dry and inspect during refits if there is any sign of moisture migration through the wall. In salt-air environments, good practice is to keep connections clean, avoid leaving the box open during construction, and close out the installation promptly with the intended devices and cover plate.

We ship all in-store (FL) stock orders the same day if placed before 3 PM EST, Monday through Friday. Orders placed after this time will ship the next business day. Orders fulfilled from other warehouses or manufacturers may not ship the same day. If an item is out of stock, we will notify you promptly.