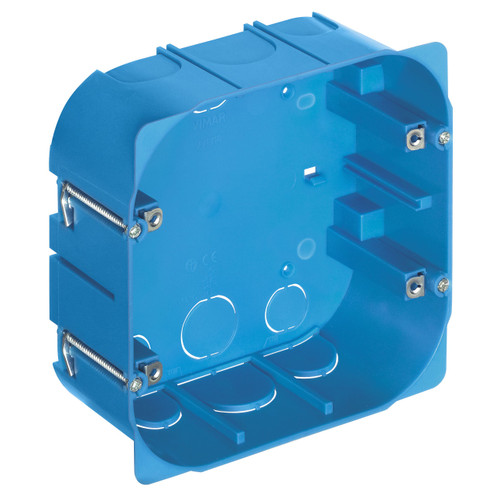

Vimar 8-Module Rectangular Flush Mounting Box, For Masonry Walls, Glow Wire 650°C, Halogen-Free Plastic, 20/25 mm Conduit Knockouts, Light Blue

-

Perfect Fit, Guaranteed

Get the right part every time

-

Expert Support

Our in-house specialists know our products inside and out

-

Enhanced Value & Service

We go beyond the sale with professional and balanced services

-

Wordwide Delivery

Enjoy hassle-free worldwide delivery

Overview

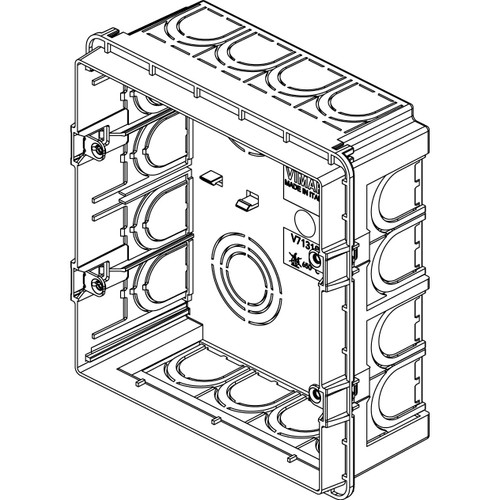

The Vimar VMV71318 is an 8-module flush mounting box for masonry walls, sized at 145.00 mm x 124.50 mm with an inner depth of 50.00 mm and an installation depth that can be set up to 56.80 mm. It gives you a clean in-wall base for mounting 8-module device supports and keeping terminations and cable routing organized behind the finished faceplate.

The light blue body makes it easy to spot during rough-in, and the box is built around typical conduit-style installations with break-out entries for 20 mm and 25 mm runs. For marine projects, it fits best in protected, building-style spaces such as marina facilities, dock utility rooms, or interior refit areas where wiring is routed in conduit inside solid walls.

Key features

- 8-module rectangular flush mounting box intended for masonry walls

- Overall size 145.00 mm (L) x 124.50 mm (W) with 50.00 mm inner depth

- Depth range up to 56.80 mm to suit different wall builds and finish thickness

- Glow Wire 650°C rating for higher heat resistance in the wall cavity

- Break-out openings for 20 mm and 25 mm conduit, with rear cable entry support

- Couplable format supports multi-box banks when using compatible coupling joints

- Zinc-plated fixing lugs help keep threads clear so device supports screw in cleanly after plastering

- Accessory-ready layout supports items such as anti-mortar covers and a rack for a dividing screen

Compatibility and fit

This box is built around an 8-module layout, so confirm the device support and front frame you are installing are the matching 8-module format. Before cutting in, check the available cavity depth and finishing layers so the box can sit flush and still leave working room for conductors behind the device.

For conduit runs, plan entries around 20 mm or 25 mm pipe sizes and use the break-out points that keep bends gentle and cable pulls clean. If you are coupling multiple boxes, keep alignment tight at the rough-in stage so the finished frames sit straight across the whole bank.

Installation and setup

Set the box into the masonry opening so the front edge lands flush with the intended finished surface. Pop the required knockouts, route conduits, and leave enough slack for terminations and device removal later. During plastering and finishing, keeping the box protected helps prevent debris from building up where the device support needs to seat and screw down.

Once the wall is finished, mount the device support by screwing it into the fixing lugs, then complete terminations and fit the faceplate. If you are dividing circuits inside the box, a separating screen can be fitted where your installation calls for it.

Use cases on board

This is a practical match for electricians and boatyard teams building out shore-side electrical areas or interior refit spaces that use in-wall conduit and modular switching. For exterior marine locations exposed to spray or washdowns, use an enclosure that carries an appropriate IP rating for the environment.

We ship all in-store (FL) stock orders the same day if placed before 3 PM EST, Monday through Friday. Orders placed after this time will ship the next business day. Orders fulfilled from other warehouses or manufacturers may not ship the same day. If an item is out of stock, we will notify you promptly.